The perfect fitting with diamonds

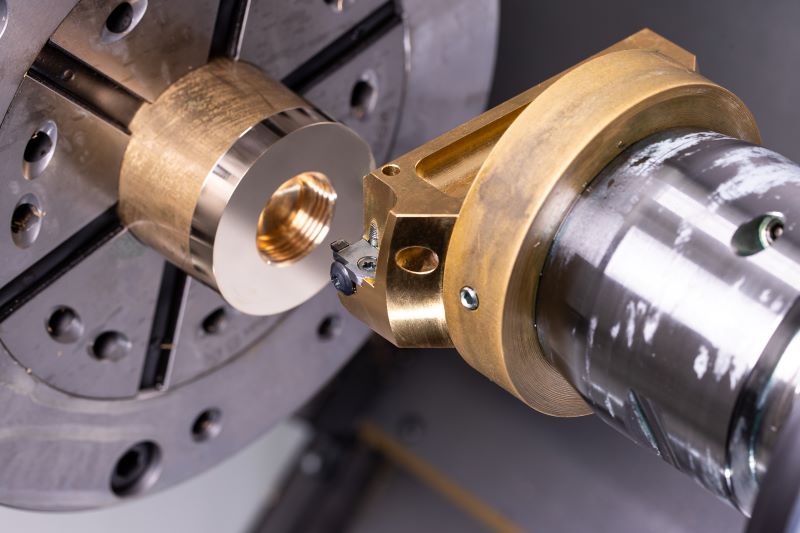

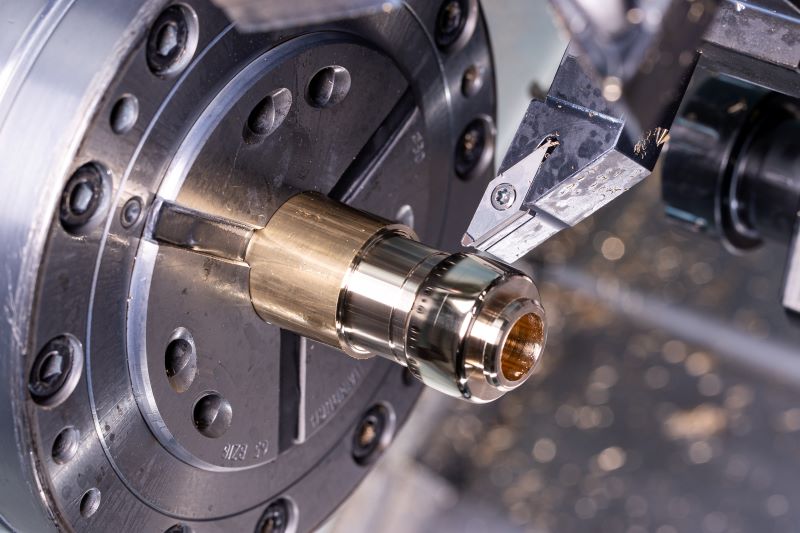

Designers, architects and discerning clients - when planning bathrooms or kitchens, they all place high demands on the taps installed. The design of the taps and shower heads must fit seamlessly into the overall interior design concept. The Belgian company RVB shows that not all taps are the same. The manufacturer produces its high-quality taps in Brussels, through which water flows worldwide every day. Production Manager Louis-Philippe Gillieaux relies on modern CNC machining centres and manual work in production. To ensure the high quality of his products, he relies on diamond tools from Paul Horn GmbH for high-gloss surfaces.

"The quality of the surfaces is very important. It should be precisely cylindrical or, in the case of shallow fittings, perfectly flat. We can't achieve this precision by polishing," says Gillieaux. A polished surface plays and shines, but it is not flat. This is why polishing is not a geometrically precise manufacturing process, even if it is done by a machine. The best possible polishing results cost a lot of time and money. "Finding a good polisher is very difficult.It's a job that not many people want to do because it's very demanding," says Gillieaux and continues: "To further increase the quality of our premium fittings, we coat these fitting parts with a layer of copper and nickel before chrome-plating or gold-plating, just like in the old days. This enhances the subsequent shine and colour impression and improves the adhesion of gold and chrome to the brass base material, which contributes to an even longer service life of the fittings. Although polishing produces a high lustre, it is not a geometrically precise processing method, as anyone who knows anything about polishing will tell you. Polishing away one µm too much on a geometric control surface on the brass part destroys the perfect impression of the subsequent mirror finish. These tiny geometric errors are particularly noticeable on rotationally symmetrical or flat mirror finish surfaces."

Monocrystalline diamonds

For these reasons, Gillieaux and his team have been using MCD tools for over 15 years. When used, the monocrystalline diamonds produce surfaces that make subsequent polishing unnecessary. The switch to machine production not only resulted in a high increase in quality, but also in cost savings. "By using diamond tools, we have greatly reduced the cycle time," explains Gillieaux. Before switching to the diamond tool systems from Horn, the team used tools on which the diamond was soldered directly onto the tool holder. Due to the cumbersome handling and the time-consuming servicing of the tools, they were looking for a modular tool solution. The arguments put forward by Horn technician Kees van Bers convinced Gillieaux and his team.

Today, RVB relies on a wide range of Horn MCD tools. The high-calibre inserts are used on conventional CNC machines. "You don't need special machines for milling and turning high-gloss surfaces. The quality is produced by the inserts," explains van Bers. In addition to turning tools, Gillieaux also relies on MCD milling tools. "We were sceptical at first because of the high cost of the cutting tools, but the performance and results have now completely won us over," says Gillieaux. When asked about the tool life of the tool systems, van Bers jokes: "With an infeed setting of around 0.02 mm in brass, the tool life is 'eternal'. If an insert does become blunt, it can be re-polished up to 20 times - with the same "eternal" tool life. The greatest danger for MCD tools is operator error."

The supreme discipline in machining

High-polish machining with MCD is one of the supreme disciplines of metalcutting processes with geometrically defined inserts. Two hundredths of a millimetre of finishing allowance separate a very good surface from the perfect surface with a mirror finish. The range of applications is broad. The manufacturing process is used in numerous industries. In the jewellery industry, for example, the tools provide the shine in the production of visible parts of a high-quality wristwatch and most wedding rings. In the production of mirrors for space telescopes, the almost perfect dimensional accuracy of the milled mirror surface guarantees a distortion-free view into space. Diamond-tipped tools were used in the manufacture of almost every visual aid, whether spectacles or contact lenses. Another possible application is in tool, model and mould making. Here, time-consuming and expensive polishing work can be saved. The list goes on, and these tool systems are firmly established, not least in the medical industry.

The quality of the tool cutting edge plays a decisive role in producing surface finishes with a mirror finish. The quality of the cutting edge is reflected in the surface to be machined. The final inserts or polishing of the MCD cutting edge resembles craftsmanship. Similar to the cutting of a jewellery diamond, the finishing of a tool cutting edge for high-polish machining is done by hand using grinding pliers. Air-bearing grinding tables with a solid granite table top provide optimum conditions for grinding the inserts. A microscope with 200x magnification is used for visual inspection. Under this magnification, the cutting edge must be absolutely free of nicks. The resulting insert has a maximum radius of 0.0002 mm. Horn has developed a special grinding machine for grinding MCD ball nose end mills for high-polish machining of free surfaces, with which even the smallest radii can be reliably ground.

Synthetic diamonds

Horn relies on high-purity MCC diamonds to equip its MCD tools. These monocrystalline stones are created using the CVD process. Various gases, mainly methane, are used as a carbon source, which are deposited during the process and allow the diamond to grow. The diamonds are characterised by their crystal clear to, depending on their thickness, slightly brownish colour. A major advantage of this process is the possible edge length of the stones. This means that even long tools with cutting edge lengths of 30 mm, for example, can be realised. Previously, natural diamonds had to be used for such tools, which are difficult to realise due to their high price, availability and natural inclusions.

International designers

The MCD inserts are used at RVB in over 50 different fitting parts. The design of the various series of fittings comes from international designers. "The design is the most important feature for successful competition," says Gillieaux. To this end, RVB works closely with renowned artists. "The designers get in touch with us with their ideas. If they match our DNA and are technically feasible, we realise them in a series," says Gillieaux.

The partnership between RVB and Horn has existed for over 15 years. In addition to MCD tools, the team also relies on Horn tools for grooving and parting off. "No matter what requirement we contact Horn with, we are always presented with the appropriate solution for us. The service doesn't stop after the sale. The Horn technicians keep at it until the production process runs perfectly," says Gillieaux.

The engineer Gaston van Bastelaere founded the RVB company in 1935. In 1936, van Bastelaere patented his first inventions, including the FOR valve system. This ensures that the tap closes perfectly in 1/3 of a turn by preventing the seal from being squeezed. A small revolution even then. With numerous other developments and bold designs, the entrepreneur was often ahead of the trends in the tap industry. The shapes and functions of RVB taps are still contemporary today. In 2004, Alain Gillieaux bought the company and modernised it fundamentally. However, he always took care to retain the in-house expertise. Louis-Philippe Gillieaux continues the company with the same approach.