In the field of additive manufacturing, HORN covers the entire 3D

printing process chain: From consulting, design, 3D printing, heat

treatment and machining to surface treatment and quality assurance.

The Laser Powder Bed Fusion (LPBF) process and a Trumpf TruPrint 3000 Dual Laser machine are used.

The materials available for individual customer solutions include:

- Aluminium 3.2381 (AlSi10Mg)

- Stainless steel X2CrNiMo17-12-2 (1.4404 / 316L)

- Tool steel X3NiCoMoTi18-9-5 (1.2709)

- Titanium 3.7165 (Ti6Al4V)

- As well as other materials on request.

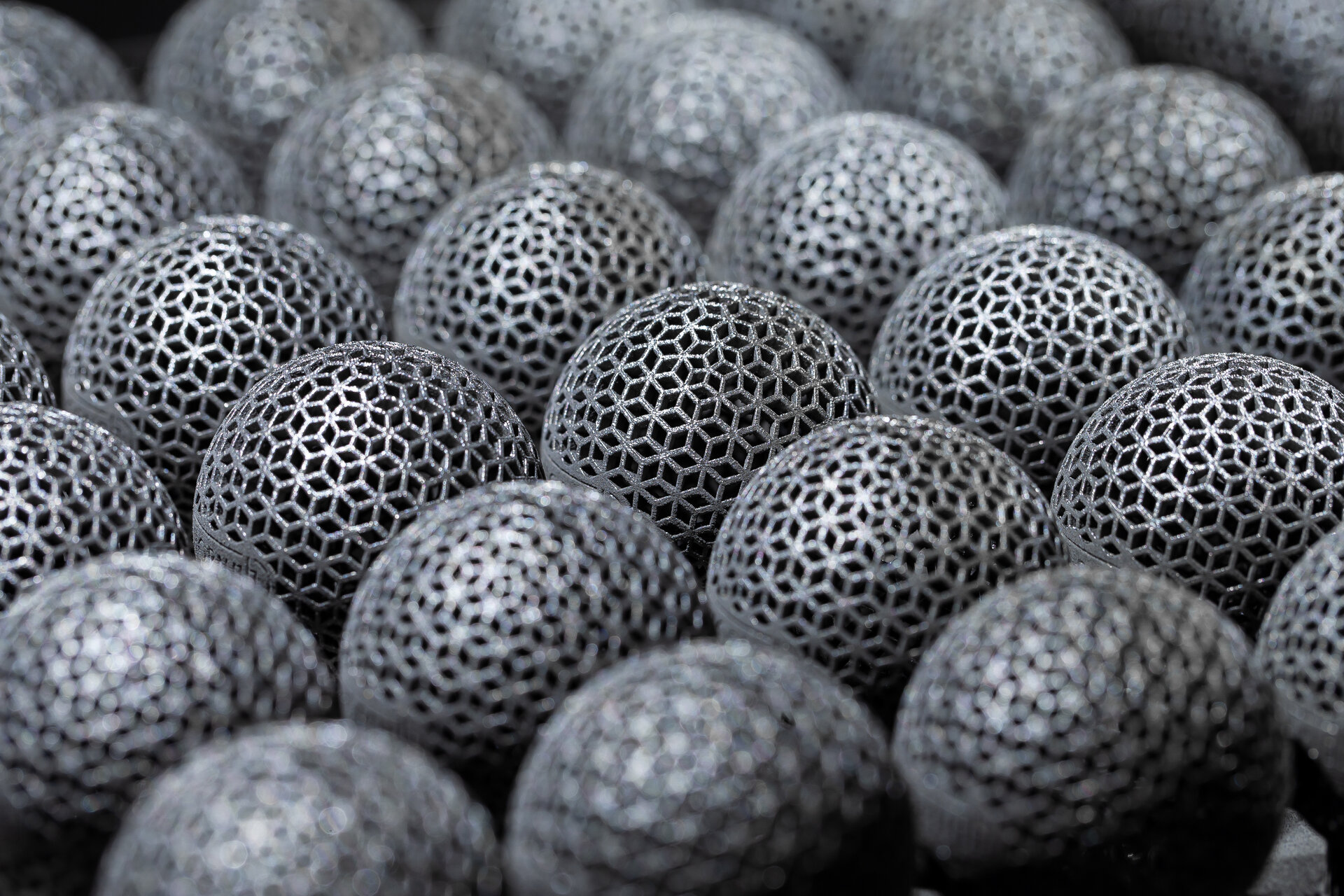

The technologies used enable the production of complex parts or special tool designs that were previously difficult or impossible to manufacture using conventional production technologies. Among other things, this enables weight optimisation through lightweight structures such as honeycomb or fine lattice structures. In addition, highly complex components with integrated functions, such as functional prototypes, can be made from production-grade materials. Development times are significantly reduced and even individual items or very small batch sizes become economical. In addition, components can be customised - for example with company logos, lettering or integrated design features. Even internal, conformal cooling channels can be integrated.

Users benefit from expertise in LPBF process analysis. When producing components, HORN assists in determining individual laser parameters for the powder bed process and offers advice on everything from the manufacturing strategy to the optimisation of additive components. All 3D printed parts are produced at HORN as customised solutions, precisely tailored to the user's requirements. They can be delivered either directly as a raw part from the printing process, or fully post-processed. Thanks to many years of experience - from design and machining to supply of the finished component - HORN offers a consistent and high-quality manufacturing process. Heat treatment and surface treatments, such as sandblasting or vibratory finishing, are also part of the service portfolio.

In collaboration with Research & Development, HORN's additive manufacturing team is continuously developing new solutions and concepts for 3D-printed tools tailored to user requirements. Additive technologies are also used in HORN‘s own production, for example in the form of specially developed 3D-printed cooling channel nozzles for grinding carbide tools. Urgently required spare parts or tools for maintenance can be realised quickly, significantly reducing machine downtime.

Do you have any questions?

We are there for you personally and are happy to take care of your issues.