Extensive product portfolio for almost every grooving operation.

Decisive factors for a reliable and economical grooving process: the quality of the carbides used, as well as of the cutting edge and insert coating.

Adequate supply of coolant.

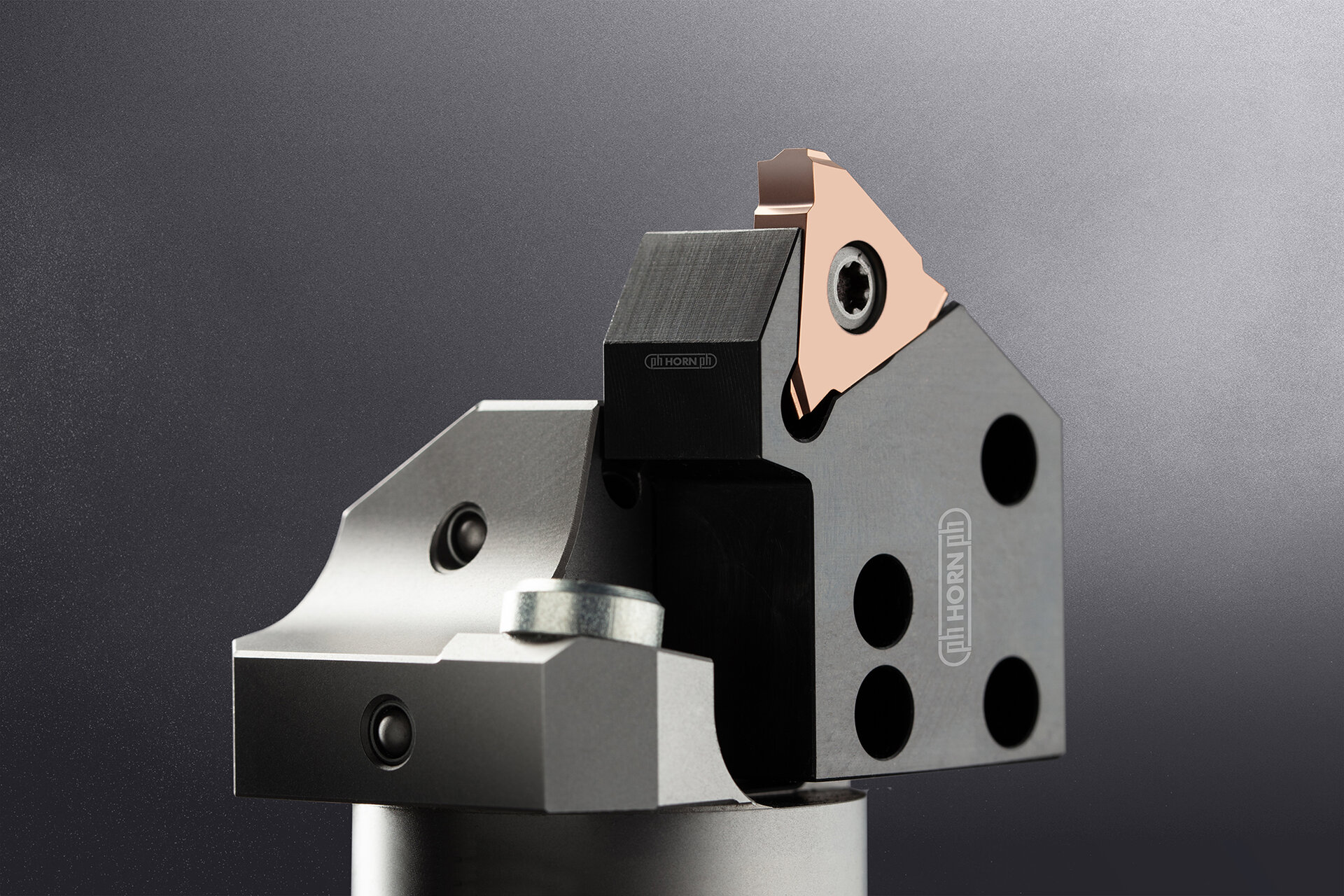

Numerous tool systems such as S229, S100 or S117 make Horn a specialist for machining between flanks.

Continuous development and optimisation of successful product families.

100 percent of the added value of the product range is created in Horn's own production facilities.

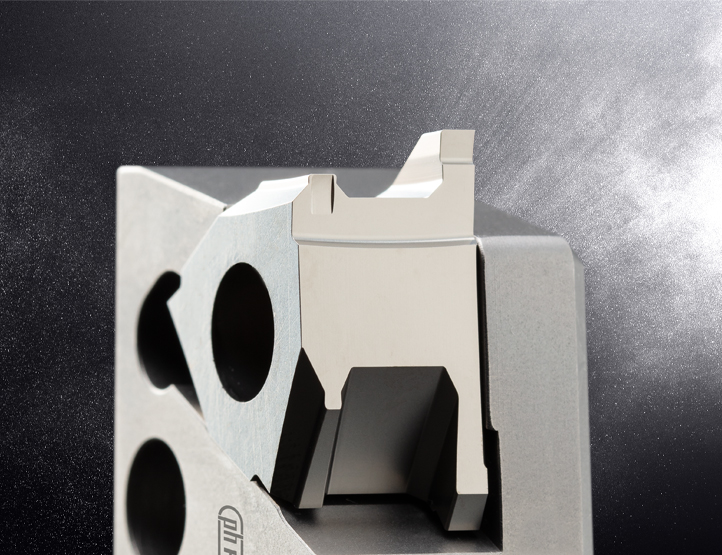

The cutting edge penetrates the workpiece in a radial or axial direction.

Control of chip flow.

Different chip breaking geometries for reliable chip width reduction, chip control and chip breaking.

Grooving

Grooving, parting off or trochoidal grooving: Grooving is considered the pinnacle of turning operations. The machining process with indexable inserts has become an integral part of modern production and is part of everyday life in the machining industry. With over 50 years of expertise in the development of grooving tools, Horn is a partner and problem solver for machining between flanks. Horn offers a broad product portfolio for almost every grooving operation, including internal, external and axial grooving.

The grooving process basically involves a narrow cutting edge that plunges into the workpiece in a radial or axial direction. The art of grooving is, among other things, controlling the chip flow. Swarf build-up, chip jams or long tangled ribbons must be avoided, as they have a negative impact on process reliability and can lead to tool breakage and scoring of the flanks. Depending on the material to be machined and the type of machining, Horn has developed different chip breaking geometries that ensure reliable chip width reduction, chip control and chip breakage. Another important point for economical grooving is a sufficient supply of coolant. Whereas in the past, cooling was carried out from the outside using classic flood coolant, today modern tool carriers are used usually with an internal coolant supply. This ensures effective cooling of the shear zone between the tool cutting edge and the workpiece. For parting off, Horn also offers a type S100 insert, which supplies the contact zone with coolant at high pressure directly through the insert. Tools are exposed to high loads during parting off. The quality of the carbide used, as well as the quality of the cutting edge and of the insert coating also play a decisive role in ensuring reliable and economical parting-off.

In 1972, Horn introduced the three-edged type 312 insert, which is still popular with users today. However, it is not only the type 312 indexable insert that has made the precision tool manufacturer a specialist for machining between flanks. Numerous other tool systems, such as the S229, S100 and S117 systems, followed on from the 1972 idea and are now used successfully worldwide for grooving. Horn has never stopped developing and optimising successful product families. At the same time, Horn has integrated 100 percent of the added value for its entire product range into its own production.