A new era of European space travel

At 8:59:50 pm on 9th July 2024, engineers sat tensely behind countless monitors and listened to the countdown: 10, 9, 8, 7... At exactly 9:00 pm German time, the word "Décollage" (French for "take-off") was uttered. Amidst a roaring tail of fire and huge clouds of steam, the new Ariane 6 launch vehicle lifted off into space from Kourou in French Guiana. The team in Kourou was in a celebratory mood after the first mission. But the excitement was not only there. The launch was shown on public screens at all ArianeGroup sites. "We have been eagerly awaiting this moment for eight years and have worked hard for it," says Stefan W. He is responsible for the metalcutting processes for ArianeGroup engines at the Ottobrunn site. The manufacture of the individual components and assemblies is literally rocket science. Due to the extremely tight tolerances, exotic materials and high component costs, it is crucial that nothing goes wrong during production. Stefan and his experienced machining team rely on the precision tools and technical expertise of Paul Horn GmbH.

Vinci and Vulcain 2.1 are the names of the two rocket engines that power the new Ariane 6. With around 130 tonnes of thrust each, equivalent to four million horsepower, the engines are marvels of engineering. Unlike conventional aircraft turbines, rocket engines do not draw in air from outside, which is then compressed and accelerated before being expelled. The thrust is generated by expelling propellant in the opposite direction to the direction of propulsion (recoil principle). This is why rocket engines can deliver the necessary thrust even in the vacuum of space, whereas aircraft engines would have no air to suck in. The necessary thrust is generated by burning liquid oxygen (LOX) and liquid hydrogen (LH2). Under the high pressure of turbo pumps, the mixture is ignited in the engine's combustion chamber. The resulting pressure is converted into kinetic energy.

De Laval nozzle

A de Laval nozzle is connected directly to the combustion chamber of an engine. The specially shaped outlet serves to increase the exit velocity, which leads to greater thrust and higher internal pressure in the combustion chamber. The high temperatures during combustion of the fuel mixture require active cooling. The structure of the nozzle can be imagined as a tightly fitting spiral of thin Inconel tubes that are welded together. The cryogenic fuel flows through the thin tubes, cooling the inner walls of the nozzle.

Effective cooling is also crucial for the combustion chamber, which is the central component of a rocket engine. At an internal temperature of around 3,500 degrees Celsius (6,332 degrees Fahrenheit), cooling is actively provided by channels through which the cryogenic fuel flows under high pressure. However, anyone who thinks that the combustion chamber is made of high-temperature nickel-based alloys is mistaken. ArianeGroup manufactures the combustion chambers for the Vulcain 2.1 and Vinci engines from a special, patented copper alloy. "The simple reason for this is the high thermal conductivity of the material," explains Stefan W. The cooling channels are milled into the outer surface of the combustion chamber in a special configuration.

HORN tools in use

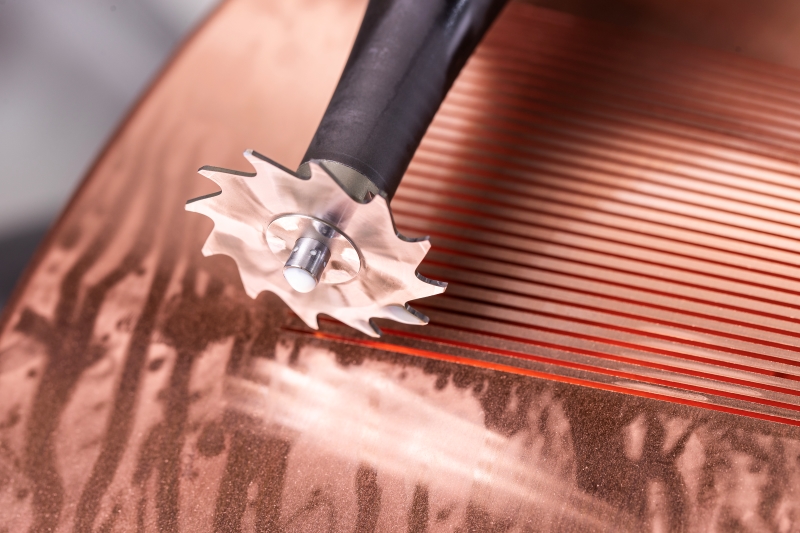

The forged blank weighs around 700 kg (1,543 lbs) when the employees clamp it onto the WFL turning/milling centre. After contour turning, the coolant grooves are milled. During initial trials in the development phase, this was done with conventional side milling cutters. The Ariane team contacted the HORN sales representative, Michael Götze, to find a better tool solution. "Almost every time we visit Ottobrunn, we are presented with new tasks that require tooling. These are exactly the kinds of challenges that allow us to demonstrate what is technically possible with our tools."

The machining application was clear: milling the slots, just a few millimetres wide and deep, in a single cut while maintaining tight tolerances. In addition, high surface quality of the flanks and base of the grooves was required. "In addition to the tolerances, it was also important to us that the grooves were virtually burr-free," explains Stefan W. Götze suggested milling the cooling channels with the HORN DG tool system. With the modular DG interchangeable head milling system, HORN offers a highly accurate, economical and resource-saving tool system. It achieves high precision through the use of a guide pin, a precision trapezoidal thread and a taper/face contact. Repeatability is to within microns. "We have numerous standard versions of the system. For special customer requirements, it can be easily adapted to the respective machining application," says Götze.

Special solution brings success

A special solution from the DG system is used for milling the grooves. The tool underwent several optimisation phases in a series of trials. The team tested a total of seven different variants. The individual inserts are ground to a sharp edge and offset from each other to ensure virtually burr-free machining. The internal coolant supply directs the coolant to both flanks of the inserts. In addition to high precision and long tool life, this allows the chips to be flushed out of the narrow grooves. The solid steel tool holder is a finely balanced shrink-fit variety, ensuring low-vibration machining despite the long overhang.

The tool mills several hundred metres of coolant slots into the combustion chamber. The required tolerances and surface finish can be reliably achieved with the machining strategy. "At the beginning, we had the problem that the surface quality was ideal. The groove flanks must have a certain roughness for the next production operation. It is not easy to produce a poor surface with a good tool. However, we managed to do this by adjusting a few parameters," says Stefan W.

Less than a centimetre between hell and the Arctic

The cooling channels are sealed using an electroplating process. After machining, the technicians apply a special wax to the grooves. This is where the problem of an excessively good surface finish becomes apparent. If the surface is too smooth, the wax does not adhere. The outside of the combustion chamber is then nickel coated. After electroplating, the wax is removed from the channels using heat and pressure. During operation, liquid hydrogen acts as a cooling medium, flowing through the channels under high pressure before providing sufficient thrust in the combustion chamber. The high thermal conductivity of the copper alloy is key to preventing the combustion chamber from melting during operation.

"Our top priorities are care and precision. That's why we place very high demands on the selection of tooling systems. HORN is one of our top suppliers in this area," says Stefan W. ArianeGroup also manufactures numerous other components at its Ottobrunn site, such as turbo pumps for fuel injection. Final assembly of the engines takes place at the Bremen site.

28,000 km/h (17,398 mph)

The Vulcain 2.1 engine is a further development of the version installed in the Ariane 5 rocket. The engine is used in the main stage of the Ariane 6 and is even more efficient than its predecessors. The engine can be swivelled seven degrees in all directions for course correction during flight. However, the 130 tonnes of thrust provided by the Vulcain 2.1 are not sufficient for Ariane 6 to take off. The engine contributes only around ten percent of the required thrust for launch. During the launch phase, the actual thrust is provided by the boosters. In conjunction with the boosters, the engine reaches an altitude of 150 kilometres (93 miles) in the first eight minutes. After reaching a certain altitude, the boosters separate and the Vulcain 2.1 alone takes over the thrust. The payload is ultimately accelerated to a speed of 28,000 km/h (17,398 mph) by both the Vulcain 2.1 and Vinci engines.

Once the rocket reaches a certain altitude, the upper stage separates from the main stage. In simple terms, the rocket splits into two parts. After the lower part separates, the Vinci engine ignites in the upper section (upper stage). While the lower part of the rocket plunges into the sea, the upper stage continues on its way into space. The special feature of the newly developed Vinci engine is that it can be ignited several times. This means that the upper stage can enter into different orbits. This possibility of reignition is a unique feature of Ariane 6.

Launch weight up to 870 tonnes

Depending on the payload fairing, the Ariane 6 is between 56 and 62 metres (183.7 and 203.4 ft) high and has a diameter of 5.4 metres (17.7 ft). According to the payload, the rocket launches with two solid-fuel boosters (Ariane 62) or four solid-fuel boosters (Ariane 64). The launch weight of the 62-series version is 540 tonnes. With four boosters, the Ariane 64 weighs up to 870 tonnes. ArianeGroup plans to carry out nine launches per year in the future. As a rule, one rocket transports one or two satellites into their intended orbits. The individual parts of the Ariane 6 rocket come from various locations in Germany and France. The assemblies are then transported by sea to Kourou in French Guiana.

The spaceport in Kourou is one of the best-located launch sites in the world. Its proximity to the equator gives the rocket an additional speed of 461 m/s (1,512 ft/s) in an easterly direction due to the Earth's rotation. Furthermore, the proximity to the equator makes it easier to place satellites into geostationary orbit. The proximity to the Atlantic Ocean and the sparsely populated jungle help to ensure that no people are endangered during launch.

During his career, Stefan W. has participated in several launches of the Ariane space programme in Kourou. He was also on site for the assembly of the first Ariane 6. The partnership between ArianeGroup and HORN has been in place for over 35 years. The tool manufacturer advises ArianeGroup on complex tooling requirements and supports the optimisation of demanding machining processes.

ArianeGroup

ArianeGroup is an industrial organisation that carries out missions to secure sovereignty in the fields of space and defence. With more than 8,300 highly qualified employees in France and Germany, ArianeGroup has unique expertise in accessing space. The company's expertise covers the entire spectrum of civil and military launch vehicle systems, from design, development, manufacturing, integration, flight preparation and maintenance to dismantling. ArianeGroup is the prime contractor for the European Space Agency (ESA) for the European launch vehicle Ariane 6 and for the French Defence Procurement Agency (DGA) for the M51 strategic ballistic missile of the French Oceanic Deterrent Force.

As a globally recognised specialist in innovative and competitive solutions, ArianeGroup has mastered the most advanced technologies and applications, from fuel chemistry and composite materials to liquid and solid propellants and electric propulsion systems for space applications. ArianeGroup also offers a wide range of equipment and services for space, defence and industry, both independently and through its subsidiaries Sodern, Pyroalliance, Nuclétudes and APP. In the area of launch vehicles, the subsidiary Arianespace markets and operates the Ariane 6, while the subsidiary MaiaSpace develops and markets the reusable Maia launch vehicle. ArianeGroup is a joint venture between Airbus and Safran.