FURTHER USER REPORTS

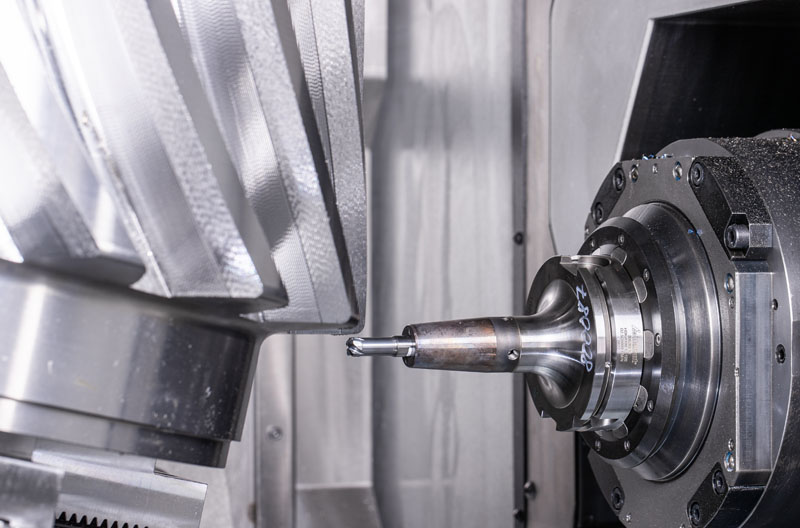

Hohes Zeitspanvolumen für eine hohe Manövrierfähigkeit

Zum Schruppen von Verzahnungen setzt Voith auf Hochvorschub-Frässysteme der Paul Horn GmbH und Boehlerit.

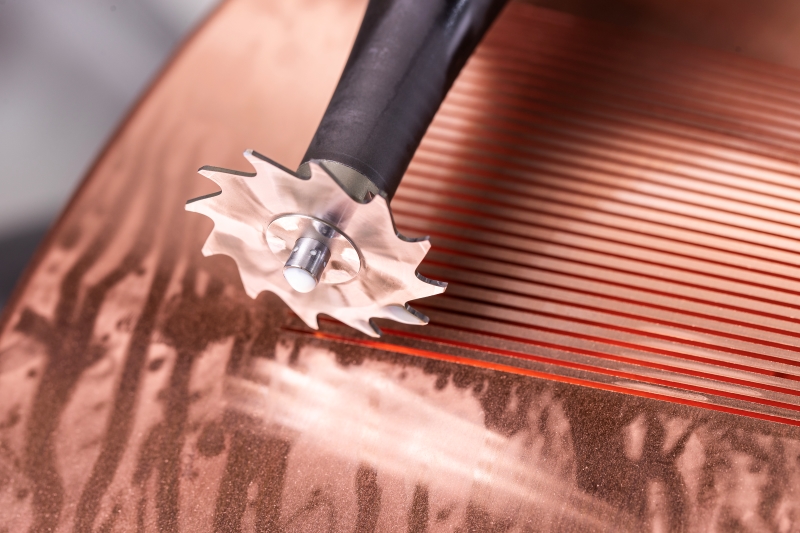

Präzise Verzahnung für die zielgerichtete Kühlung

Das Unternehmen Asch & Sebert hat einen Kühlmittelring entwickelt, bei dem sich die Kühlmitteldüsen automatisch der Werkzeuglänge anpassen. Dabei kommen Werkzeuge von HORN zum Einsatz.

Absolute precision in the battle for first place

For the 2025 race season, the Formula Student Team “DHBW Engineering” at Stuttgart University of Applied Sciences asked HORN for help in manufacturing components for the "eSleek25".

A new era of European space travel

Extremely tight tolerances, exotic materials and high component costs - nothing can go wrong in rocket science. The company ArianeGroup in Ottobrunn therefore relies on precision tools and HORN's technical expertise.

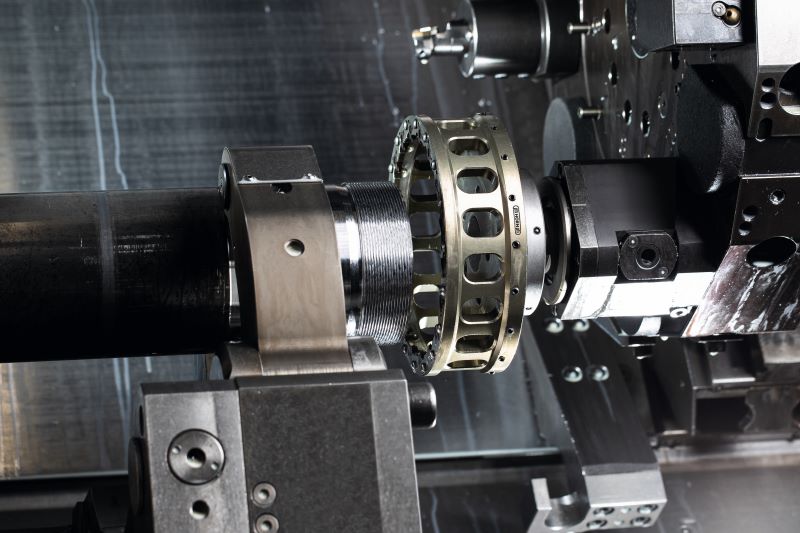

Threadcutting in seconds

For machining an external thread on a cylinder, the company Vremac from Apeldoorn switched to a special milling system from Paul Horn GmbH.

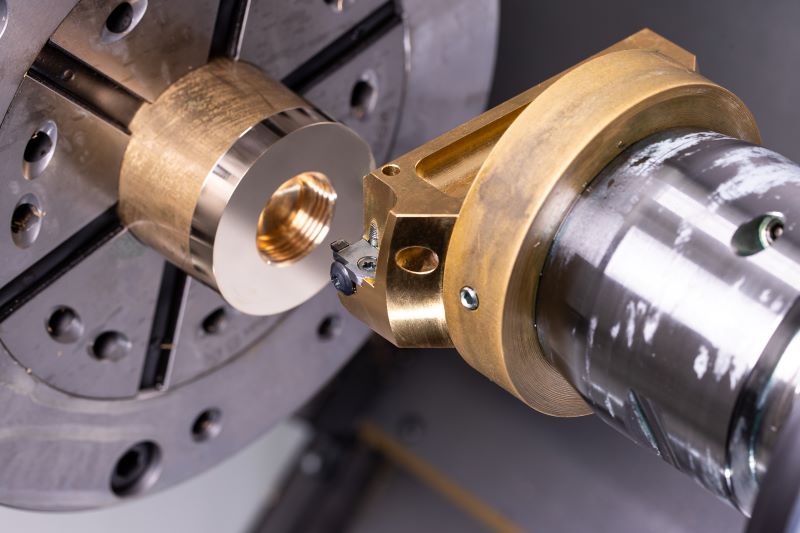

The perfect fitting with diamonds

To ensure the high quality of its products, the Belgian company RVB relies on HORN diamond tools for high-gloss surfaces for over 15 years.