Absolute precision in the battle for first place

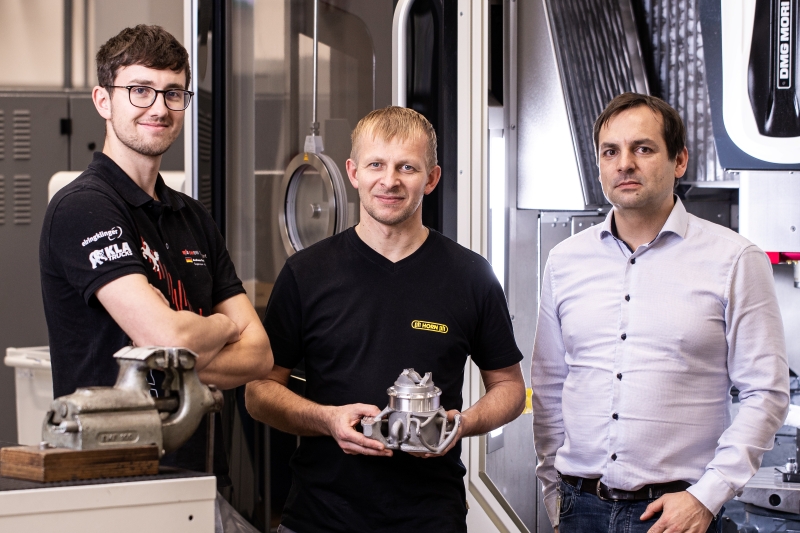

"A difference between success and failure is a matter of a few microns," says Andreas Ladner. He heads the mechanical section of the Formula Student team "DHBW Engineering" at Stuttgart University of Applied Sciences. For the car for the 2025 race season, the team asked Paul Horn GmbH for help in manufacturing components for the "eSleek25". The machining of the aluminium hub carriers for the race car posed a particular challenge. HORN Product Manager Patrick Artelt took on this challenge and developed a tool and machining concept together with specialists from HORN's production department. "The task was tricky. The component geometry is very complex and the required tolerances are to within a few microns," says Artelt.

The performance data of the Formula Student race car "eSleek25" is sure to make the hearts of sports car fans beat faster. All four wheels are directly driven by individual 38 kW electric motors. Together, the four motors deliver an output of 152 kW (around 204 HP) and catapult the car from zero to 100 km/h (62 mph) in 2.2 seconds. In total, the hub motors deliver an impressive torque of 1,400 Nm. For racing, however, the power output is limited to a maximum of 80 kW. The components for the electric drive are proprietary developments of the team. Only the individual battery cells have been bought in. The battery has a capacity of 6.82 kWh at an on-board voltage of 600 volts.

A new race car every season

A new race car is driven for each Formula Student season. Just like the race car, the team is also reassembled almost every year. This means that each new team carries out the development, production, assembly and testing of the race car independently and participates in the races. The experience gained in previous seasons is incorporated into each new development. The DHBW Stuttgart team consists of 110 members who are divided into different departments. They include, for example, mechanical components, electrics and aerodynamics. "We have a fantastic team. Every single department is absolutely passionate about their respective tasks," says Ladner.

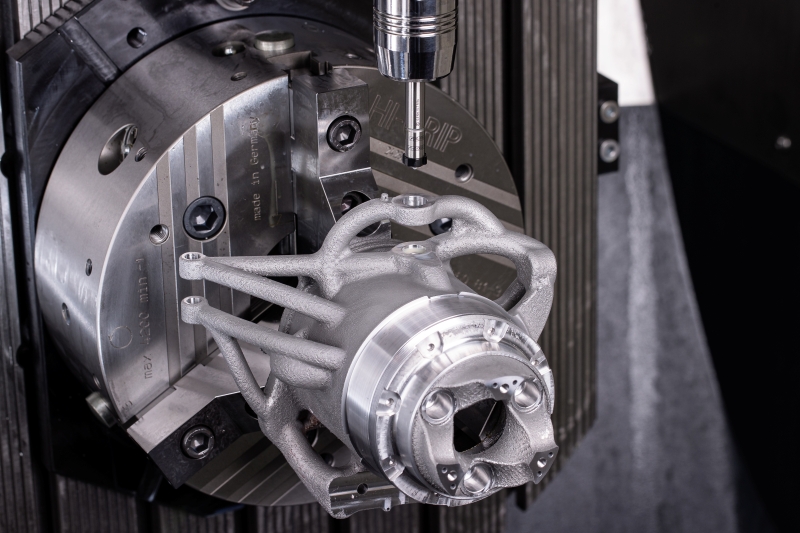

One of the biggest challenges in the production of the mechanical components are the four hub carriers. They serve to house the electric motors and planetary gears for transmitting torque directly to the wheels. The hub carriers have a complex geometry. "In racing, the goal is always to keep the weight of components as low as possible. However, this must not compromise rigidity," says Ladner. The students therefore rely on complex FEM simulations for the development of the hub carriers.

Raw part from the 3D printer

Design is one thing, manufacturing is another. Due to the complex component geometry, the aluminium raw parts are produced in a 3D printer. "We developed a manufacturing strategy for machining with two setups on a 5-axis machining centre. The profile and positional tolerances were particularly challenging," says Artelt. There is a reason for the precision required: the sun gear is directly connected to the motor. Precise alignment is therefore important, as any misalignment would cause the planetary gears to wear on one side. "Even a small misalignment would quickly cause major gear damage," says Ladner.

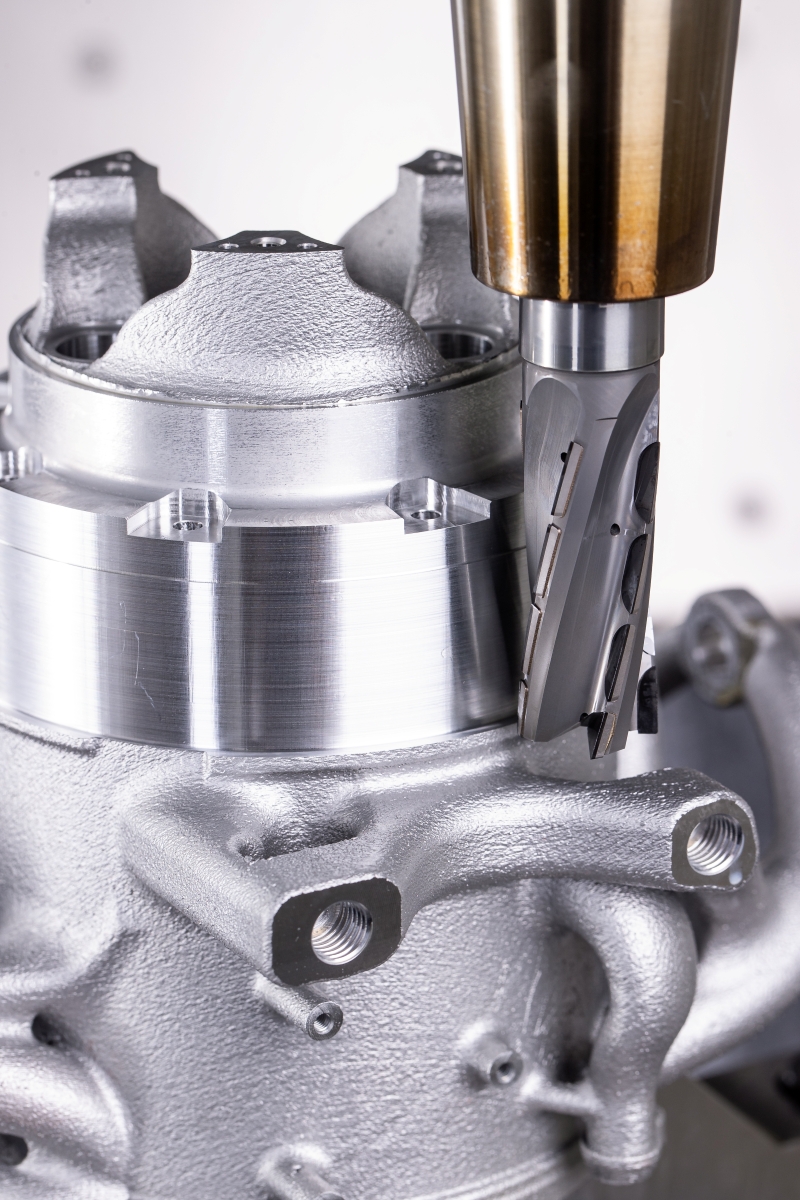

The manufacturing tolerances are in the range of 0.007 mm (0.0003"). With only four raw blanks supplied and four finished parts required, there was no room for error. In addition to the appropriately designed tool, the programming and skill of the machine operator were crucial. Twenty-seven different HORN tools are used for the various machining operations in the two setups. These include adjustable spindle tooling, reamers, PCD milling cutters and circular milling tools.

Splitting tolerances

The spindle tools took over the production of the bearing seats and an axial recess. These are where the tightest positional tolerances on the component are found. The tools can be precisely adjusted to the desired diameter. "The precise adjustment enables us to machine with micron precision to the desired tolerance. It allows us to further split the already very tight tolerance," says Artelt. A single-edged tool with a PCD-tipped insert was used to machine the bearing seats. A second spindle tool took over the production of the axial recess. It was double-edged and equipped with type 315 inserts.

Numerous HORN systems performed other complex machining operations. These included a PCD end mill. In a single clamping, it milled the diameter for mounting the wheel hub. It was chosen due to its cutting edge length and the required surface finish. The HORN DR reaming system was also used to ream the mounting points of the hub carrier.

Not only full throttle

In the individual disciplines of Formula Student, it is not only the performance of the car that counts. The disciplines are divided into static and dynamic. In the static disciplines, the business management and design approach of the team play a major role. The students have to present and justify their business plan and costings in two presentations. Another static discipline is the engineering and design event. Here, the team must convince the jury of the merits of its design and construction. This is primarily a discussion in which the jury's comments must be addressed with sound arguments and justifications.

The dynamic events include Acceleration, Skid Pad, Autocross and Endurance. The Acceleration discipline is an acceleration test on a straight, 75-metre (246-ft) track. The race cars accelerate from 0 to 100 km/h (62 mph) in under three seconds. In Skid Pad, the cars drive a course in the shape of a figure of eight. High centrifugal forces and lateral acceleration can cause the vehicle to skid in this discipline. In Autocross, the drivers drive their race cars individually around a tightly defined track against the clock. This dynamic test puts a great deal of strain on the driver and the vehicle over a distance of one kilometre. Endurance is the largest and final discipline in every Formula Student event. Here, the racing car must prove its reliability over a 22-kilometre (14-mile) circuit. This discipline accounts for one-third of the total points available.

"I am delighted to highlight the successful collaboration between the Formula Student team at DHBW Stuttgart and HORN. The joint commitment and expertise of both sides made it possible to realise the challenging project of manufacturing high-precision aluminium hub carriers," says Ladner.

Formula Student

Formula SAE was founded in the USA in 1981 and later expanded to Europe as Formula Student. Since 1999, annual events have been held in Silverstone, England, and since 2006 also in Germany at the Hockenheimring. Competitions are now also held in Italy, Spain, Brazil and Japan. Formula Student enables ambitious students to gain intensive practical experience in design, manufacturing and economic aspects of automotive engineering – all outside the lecture hall. Each team develops a single-seater race car based on a comprehensive set of rules.