Meaningful collaboration happens when each party contributes strong foundations and diverse strengths that work well together. With efficiency and shared purpose, we can create solutions that genuinely benefit our customers.

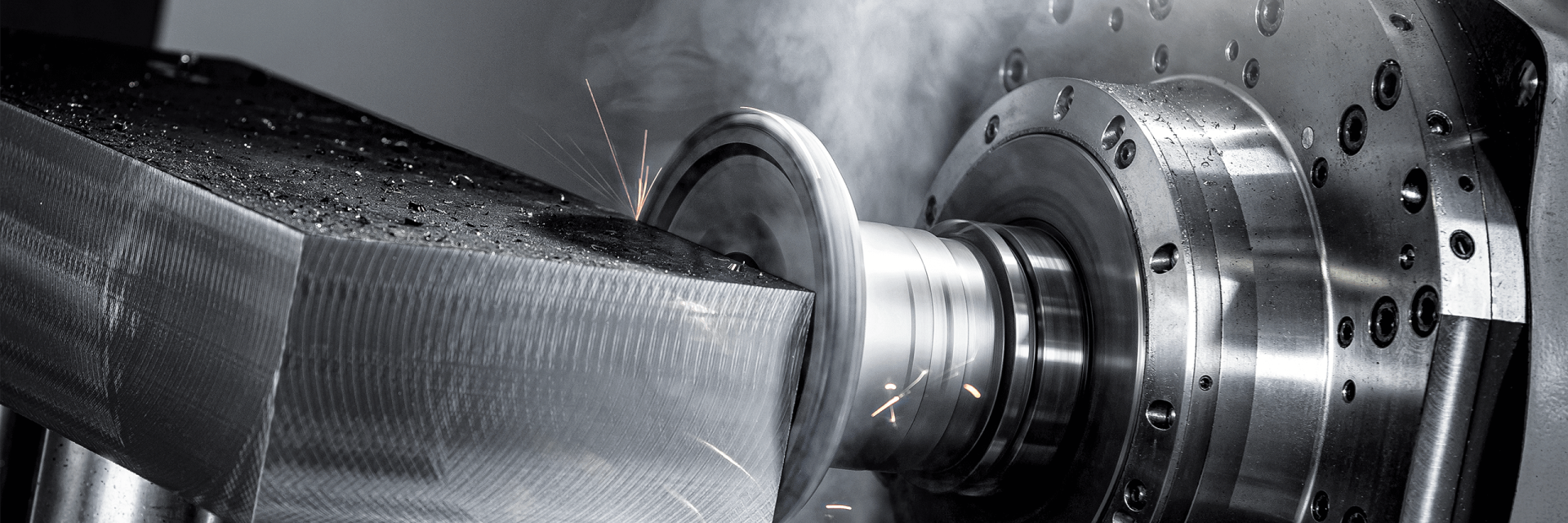

BoehleritBeginning in 2016 HORN Group entered a sales cooperation partnership with Boehlerit. This partnership was born from the desires of our customers to have an even broader tool selection. With Boehlerit's ISO milling and turning, bar peeling, and rail transit track-milling tools HORN is able to expand our already expansive portfolio to include niche industrial processes as well as ISO tooling allowing our customers to truly get all of their cutting tool needs from one source.

Graf

The cooperation between HORN and GRAF focuses on tool systems for CNC sliding-headstock automatic lathes, CNC short parts turning and multi-spindle automatic lathes. Special attention is paid to the patented, internally cooled tool systems for the CNC sliding-headstock automatic lathes.

URMA

HORN and URMA combine three interchangeable-head reaming systems developed for demanding fine boring in all application areas. The globally unique, interchangeable-head, modular systems allow cutting edges to be changed in seconds to within microns, without additional adjustment. This redefines reaming.

W&F

From the spindle to the tool cutting edge: offering a complete solution for customers is the aim of the cooperation between HORN and W&F Werkzeugsysteme. The focus is on equipping sliding-headstock lathes with a modular, quick-change system for static and driven tools. With this cooperation, HORN closes the gap between the cutting edge and the machine. As a result, HORN can react quickly to customer requests and optimise their machining processes.