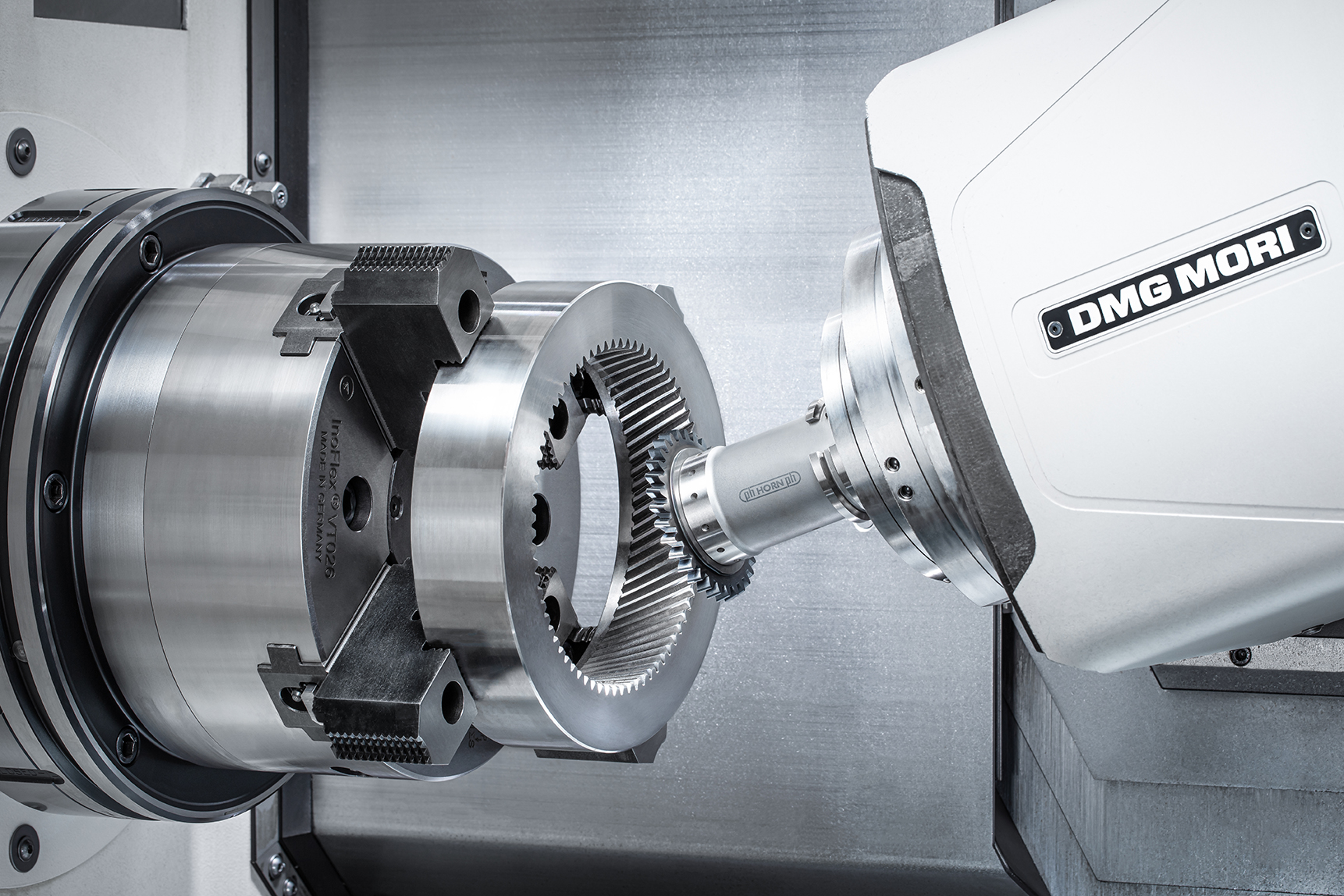

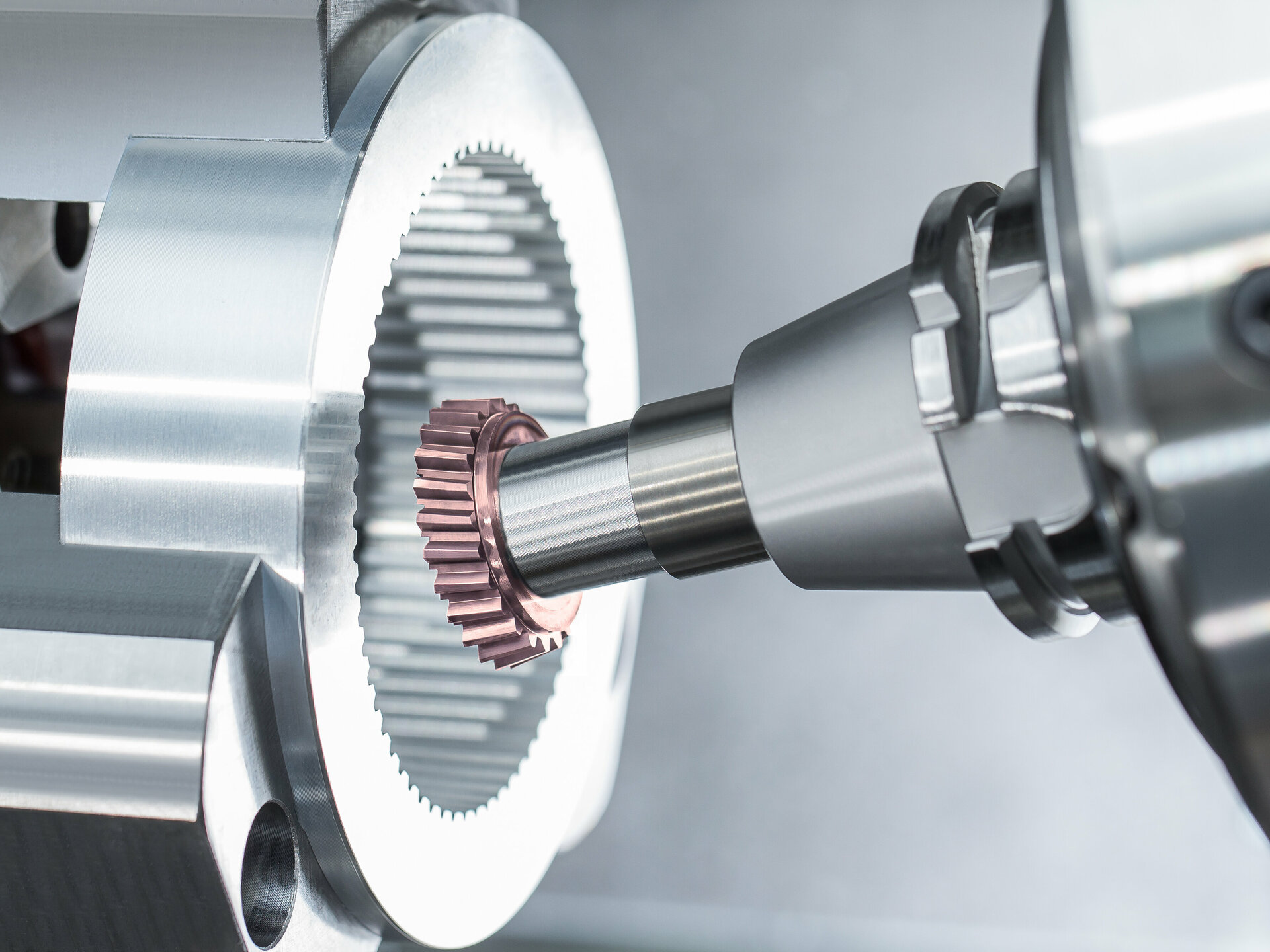

Gear skiving - on this core topic from the application area of gearing HORN and DMG Mori have launched a campaign to improve the performance of the present common solutions: the combination of machine, cycle and Tool. With the precision tool for skiving you have the opportunity to deal more intensively with this topic in practice.

technology cycle The DMG MORI technology cycle gearSKIVING is an assistant for workshop-oriented programming to increase productivity and safety as well as to expand machine capability. The advantages are a clear program structure, up to 60 percent faster programming, error minimization through dialog-guided programming, new technologies (gear cutting) and the technology know-how stored in the program. Adapted to the application On the tool side, customer-specific special tools are used. When skiving internal and external gears, module sizes up to module 8 are possible, with a gear quality of up to ≥ 7, depending on the application.

V

Instructions for use: The tool in front of you has been pre-assembled with 3 nm. Please note that when changing the tool head, the torque must be tightened accordingly.

Contact person [Hidden] CONTACT PERSON YOUR CONTACT FOR TOOLS YOUR CONTACT DMG MORI Joachim Hornung Key Account / Service Original Equipment - OEM Carbide Tool Factory Paul Horn GmbH Tel.: +49 7071 2091 Joachim.Hornung@de.horn-group.com