Whirling for excellent sound quality

Music makes people happy one moment and can bring them to tears the next. It can help drive people to peak performance in sports, or make them anxious. But one thing that music never does is leave you cold.

Further Application Stories

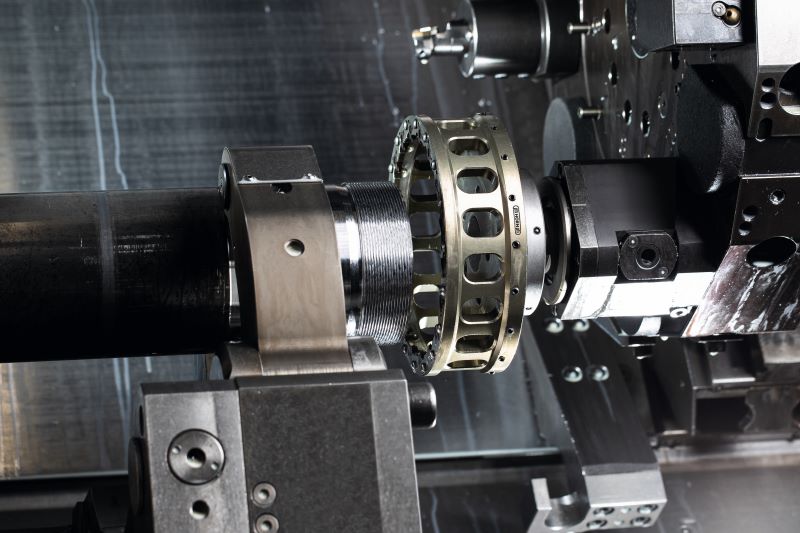

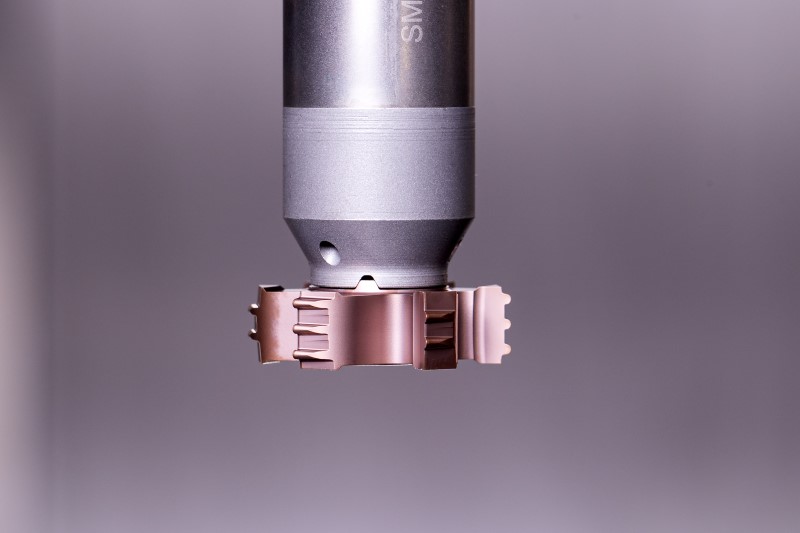

Threadcutting in seconds

For machining an external thread on a cylinder, the company Vremac from Apeldoorn switched to a special milling system from Paul Horn GmbH.

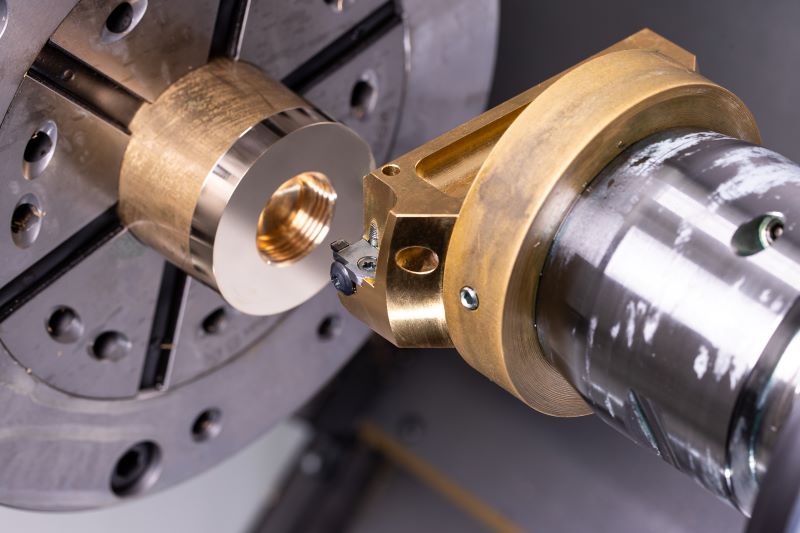

The perfect fitting with diamonds

To ensure the high quality of its products, the Belgian company RVB relies on HORN diamond tools for high-gloss surfaces for over 15 years.

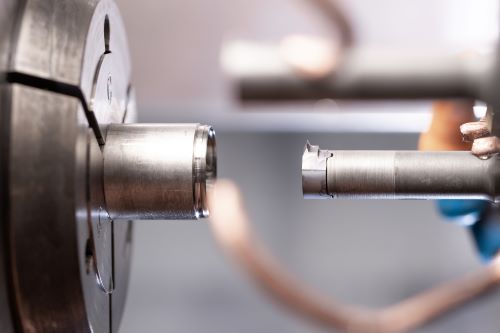

Precision is a passion

Corcym has been relying on HORN tool solutions for over 15 years. “So far, no others have delivered anywhere near as convincing a performance as the HORN products,” says process engineer Davide Ricchiari.

Chipping problems solved

The metrology company was one of the users that was able to test the new Supermini in field trials. The field tests were the first milestones in HORN’s progress.

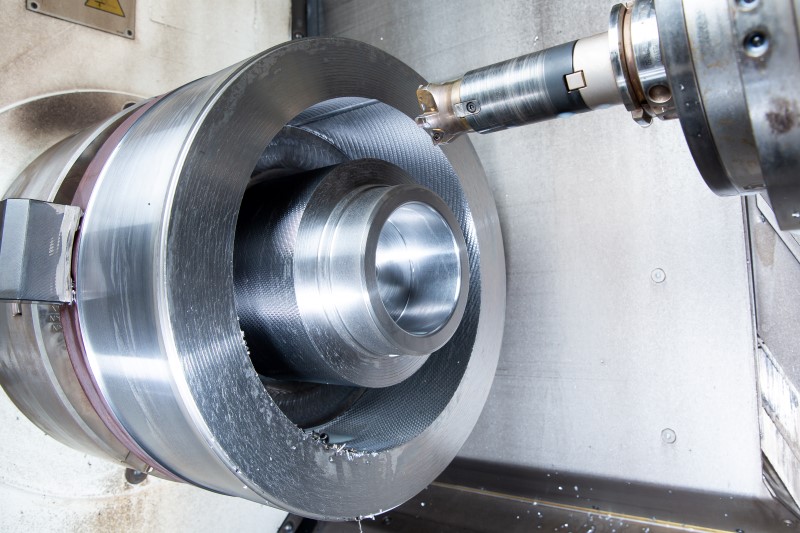

14 times faster – and even more potential

For 20 years, Bamann has relied on tools from Paul Horn GmbH in its production. The high-feed milling system DAH brought it success.

Specialities from the world centre

For milling tweezers, HG-Micro-Instrumente GmbH & Co. KG uses tool systems from Paul Horn GmbH. HORN's circular interpolation milling system offers the user a number of advantages.