Threadcutting in seconds

"We only need about thirteen seconds to produce a thread," says Ben Broekhuis. He is responsible for the metalcutting pro-

cesses in the company Vremac, Apeldoorn, in the Dutch province of Gelderland. The company is a specialist in the development

and production of hydraulic cylinders. For machining an external thread on a cylinder, Vremac switched to a special milling

system from Paul Horn GmbH. The result: approximately three times faster production than previously and a considerable

increase in tool life as well as process reliability for unmanned production.

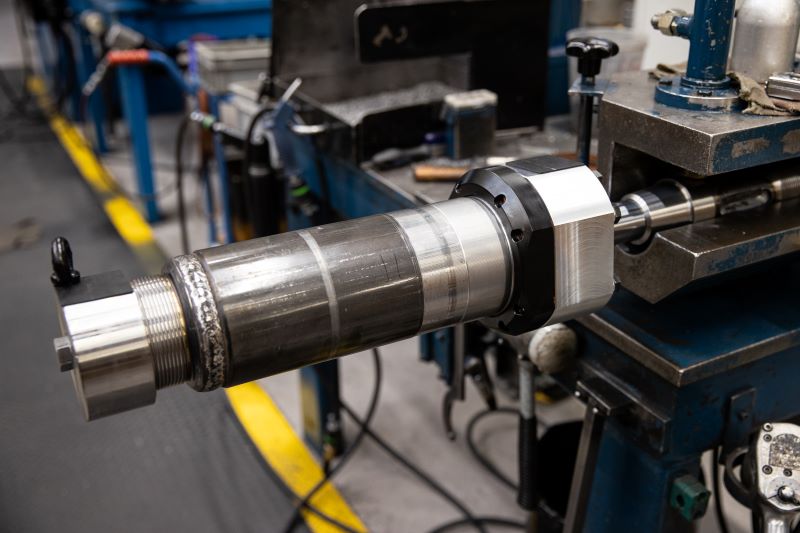

Vremac Cylinders has been involved in the development and manufacture of cylinders, accumulators and swivel joints since the company was founded over 60 years ago. In addition to the standard range of hydraulic cylinders, the company also supplies customised products. Over the last 20 years, Vremac has increasingly shifted its focus to the production of bespoke hydraulic cylinders. Vremac specialises in bores up to 1,000 mm (39.370"), piston rods up to 700 mm (27.559") and cylinders with a stroke of up to 15,000 mm (590.551"). Service and repair are also part of the company's range of services. With its many years of experience, Vremac specialises in the manufacture of hydraulic cylinders for almost all application areas. This includes preventive maintenance, spare parts management and repair on-site or at the factory in Apeldoorn.

Hydraulic moving floor systems

Vremac's range of services also includes its own products. For example, a hydraulically operated loading platform was developed in cooperation with another Dutch company. These moving floor systems are installed on trailers, semi-trailers and other loading vehicles. The system is used, for example, for unloading silage, bulk goods and wood chips in agriculture or for pallet goods. The advantage of these systems is horizontal unloading without having to tilt the trailer. Solid goods such as pallets can simply be moved hydraulically over the loading area via the rear and without a lift truck or forklift. Three hydraulic cylinders are always used for the different moving floors. One cylinder lifts the floor, while the other two cylinders move the floor slats in a horizontal direction. A travel speed of up to 2.5 m/min (8,202 ft/min) can be achieved in this way.

For the production of the cylinder components, Vremac relies on modern machinery with a high degree of automation. "Due to the large quantities of components, some machines run without operator attendance," explains Broekhuis and continues: "The process reliability of the production steps is a very important aspect of our daily work. A major problem was the production of the external thread on the cylinder housing. The M120-x-2 thread is 40 mm (1.575") long and is used to screw the cylinder cover on later. When turning the thread, long stringy swarf was produced, which either clogged the chip conveyor or filled the swarf bin too quickly. This situation required optimisation of the production strategy to ensure reliable operation during unattended shifts.

First approach

"The first enquiry we received from HORN was whether we could produce the thread by whirling. However, that process is more suitable for smaller workpiece diameters," recalls HORN application engineer Roger Kasper. Together with Joop Nijland and Roy Rademaker, sales representatives from the Dutch HORN agency Harry Hersbach Tools, he set about solving the problem. The first approach was to use a double-edged S229 insert. "Use of the HORN insert was immediately successful. We solved the main problem of long, stringy swarf but the customer was still not fully satisfied with the solution," says Roy Rademaker. A new solution was needed. The goal: even higher process reliability with small chips as well as a reduction of the cycle time.

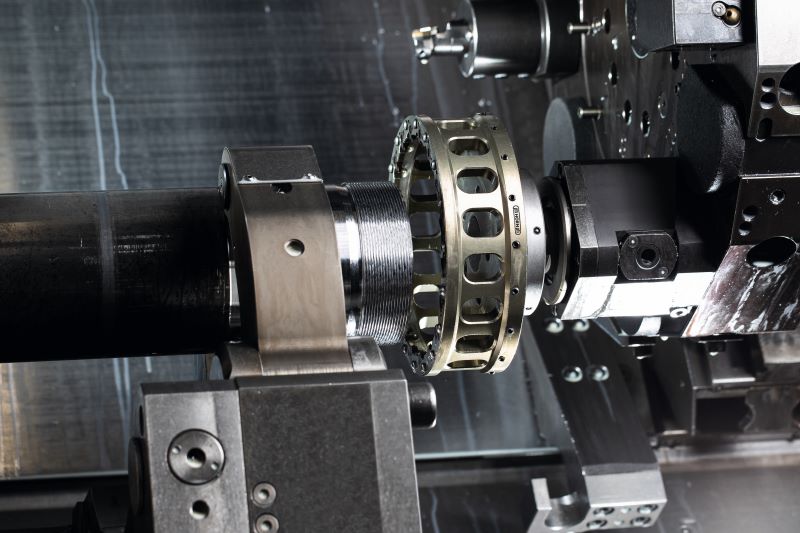

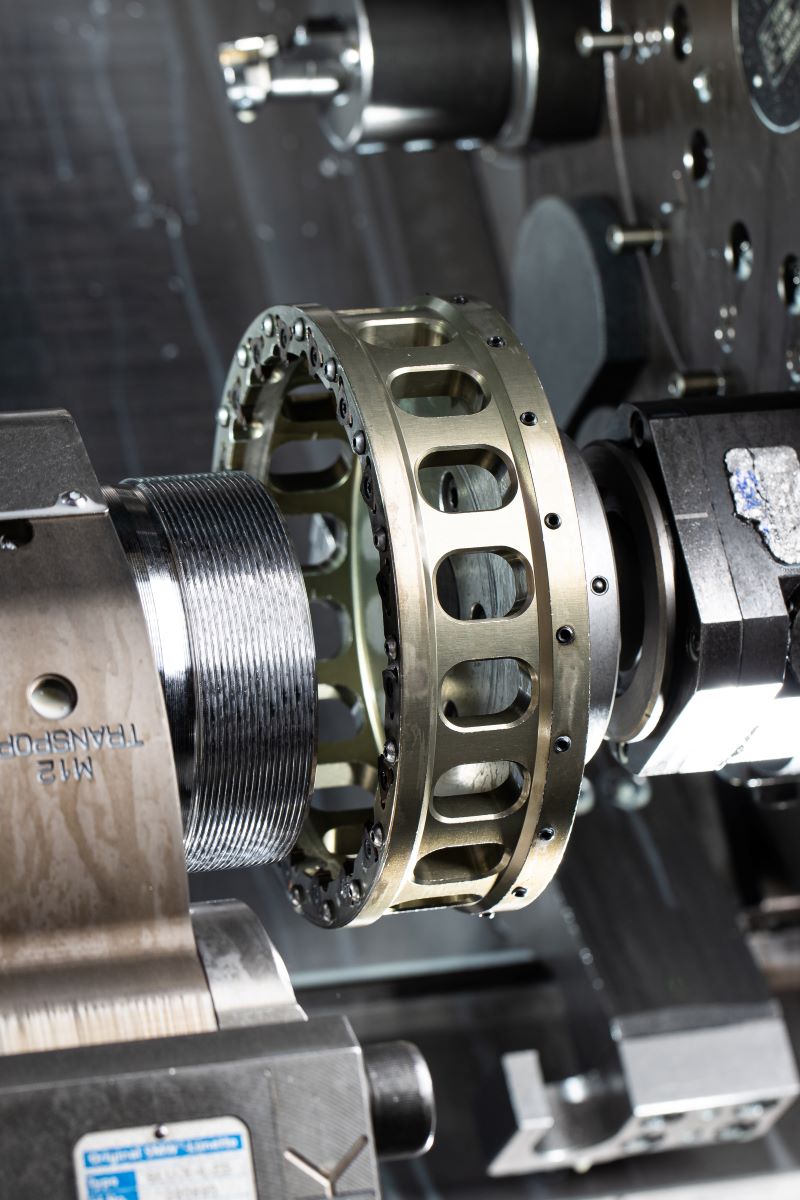

The solution was to produce the thread with a shell mill. The problem, however, was the weight of the milling cutter body. "On the machine we only have driven tools and no real milling spindle. The power would not have been sufficient for a solid steel cutter body," says Kasper. HORN solved the problem by machining recesses into the cutter body to reduce its weight. The tool was of 135 mm (5.315") diameter and was equipped with 16 three-edged S302 inserts. The first trials with the tool produced the desired results in terms of time savings and chip breaking. "We had found the right solution with the shell mill. However it was like walking a tightrope, as we were always at the maximum feasible cutter weight for the driven tool position," says Nijland.

Use in series production

The body of a shell mill resembles a bell. During machining, the tool moves over the workpiece and starts the milling process in circular movements. Such tools can be used, for example, to produce threads, grooves or other shapes on the component. Major advantages of shell milling cutters are a shorter cycle time compared to turning and better chip breaking. Such tool systems are mainly used for series production. The solution to the problem was found with the shell mill. However, in order to reduce stress on the machine's tool turret and to increase reliability even further, the HORN technicians had to refine the process further. The diameter of the tool was set at a certain ratio to the diameter of the workpiece for optimum milling. "The aim of the optimisation was to make the tool even lighter but at the same time to increase the diameter. This was not an easy task, as we were already at the weight limit," explains Nijland.

Aluminium milling body

Steel was ruled out for the larger diameter milling body due to the weight. The designers found the solution in a special aluminium alloy. With a larger diameter of 155 mm (6.102"), the new version weighs only half as much as the previous steel version.

The HORN technicians increased the number of inserts to 18. All cutting edges are cooled directly in the contact zone via an

internal coolant supply. The polygonal shank interface for the tool turret is screwed to the body. The first tests of the new milling variant were immediately successful and fulfilled Broekhuis' expectations: "Our problems have been solved. The process runs reliably and the quality of the thread produced fully meets our requirements." Before the change, the machining time was around 30 seconds for turning the thread. The shell mill reduced the production time to only 13 seconds. Furthermore, the tool solved the problem of long tangled swarf, replacing it with small broken chips. This increased the process reliability during unattended shifts, as the danger of the chip conveyor becoming blocked and the swarf bin filling up too quickly has been eliminated. Tool life of the inserts is 800 threads per cutting edge.

Increase in service life

HORN went even further by introducing a newly developed IG35 insert coating. Thanks to HiPIMS technology, the coating has very smooth properties and high heat resistance. Furthermore, the coating is free from defects such as droplets or other coating imperfections on the cutting edge. The use of the new coating increased tool life to 1,200 threads per cutting edge, i.e. 3,600 threads produced per tool.