HORN EMO Hannover 2025

(zip)Depuis sa création en 1975, EMO est synonyme dans le monde entier d'innovation, d'internationalité, d'inspiration et d'avenir dans le domaine de l'usinage des métaux. En 2025, le salon fêtera son 50e anniversaire.

En tant que salon leader mondial des technologies de production, l'EMO de Hanovre offre tous les deux à quatre ans une plateforme unique sous la devise « Innovate Manufacturing » pour nouer des contacts internationaux, ouvrir de nouvelles opportunités commerciales et obtenir une vue d'ensemble complète des offres mondiales du secteur. La dernière édition en 2023 a attiré plus de 92 000 visiteurs de 140 pays et environ 1 850 exposants à cet événement phare du secteur.

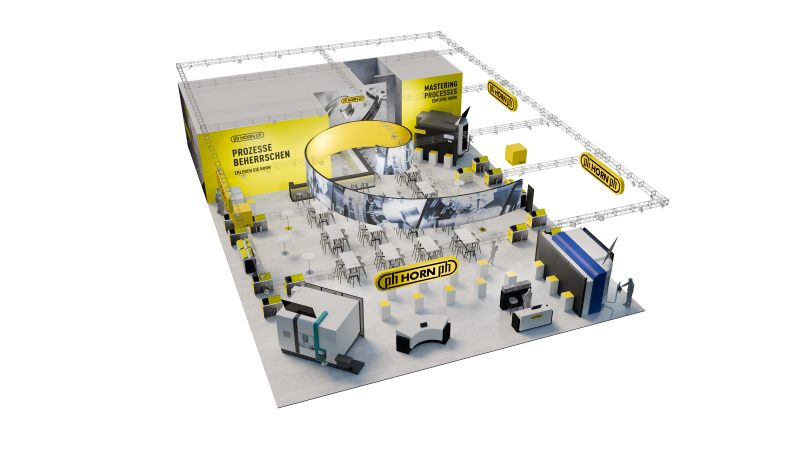

HORN présentera l'usinage pur sur 580 mètres carrés à Hanovre. Quatre machines, quatre composants passionnants, une grande variété de solutions d'outils – en action et en train de couper des copeaux pendant toute la durée du salon. Les machines suivantes seront exposées : la DMU65mB de DMG, une Index G220, une Citizen L12 et une GROB G150. De plus, nous présenterons de nombreuses pièces exposées et solutions d'outillage, ainsi que nos innovations pour 2025. Markus Horn, directeur général de Paul Horn GmbH : « Je suis convaincu que la visite du salon EMO sera profitable pour nos clients et les personnes intéressées – nous présenterons l'usinage au plus haut niveau. Sur les quatre machines, nous aborderons les thèmes de la finition, de l'usinage de matériaux sans plomb, de l'usinage de l'aluminium avec des outils PCD rotatifs et des composants technologiques avec de nombreuses opérations de tournage. M. Horn poursuit : « À mon avis, c'est le dialogue qui permet d'obtenir les meilleurs résultats, et l'EMO offre la plateforme idéale pour cela. Venez nous rendre visite dans le hall 5, stand A32. »

Outre l'usinage en direct, Horn présentera de nombreuses innovations. Parmi celles-ci figure le système Mini avec géométrie de brise-copeaux fritté, qui a été dévoilé pour la première fois lors des Horn Technology Days en mai 2025. La géométrie I frittée est particulièrement adaptée à l'usinage de matériaux présentant de mauvaises propriétés de formation de copeaux. Elle convient au tournage de copie, au tournage longitudinal, au tournage arrière et au surfaçage. C'est notamment dans le cas de faibles profondeurs de coupe dans l'acier et les aciers inoxydables que le système d'outils doté de cette géométrie démontre ses atouts en matière de contrôle des copeaux. Il permet d'obtenir une plus grande stabilité du processus et une durée de vie plus longue des outils. Lors du développement de la géométrie en I, HORN a également pris en compte l'usinage de matériaux sans plomb. Comme ces matériaux poseront un défi à l'avenir en raison de leur formation de copeaux médiocre, le fabricant d'outils propose des plaquettes avec de petits rayons d'angle à partir de 0,05 mm pour les petites avances latérales. Des rayons d'angle de 0,05 mm à 0,2 mm sont disponibles en stock.

Télécharger