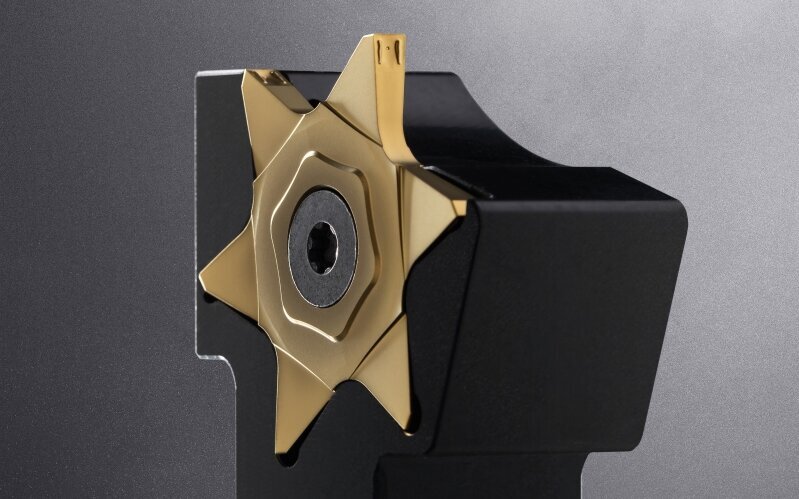

Plaquettes à six arêtes avec une nouvelle profondeur de coupe

Avec le système de rainurage 66T, Horn élargit sa gamme d'outils dans le domaine des plaquettes indexables à six arêtes. Avec six arêtes de coupe, la plaquette offre un prix attractif par arête de coupe. La profondeur de rainurage maximale est de 9,5 mm (0,374« ). C'est environ 4 mm (0,157 ») de plus que le système similaire, le 64T. En fonction de l'application, Horn propose des plaquettes avec deux géométries et une version sans géométrie. Les géométries disponibles garantissent une évacuation fiable des copeaux pendant l'usinage. La nuance de carbure IG65 est utilisée pour l'usinage des matériaux inoxydables et des matériaux difficiles à usiner. Pour les aciers courants, Horn recommande la nuance de carbure EG55 pour le système 66T.

Les largeurs de coupe disponibles sont 2,5 mm (0,098« ) et 3 mm (0,118 »). Le rayon d'angle est de 0,2 mm (0,008"). La géométrie 1A convient aux opérations de rainurage pur, tandis que la géométrie DL convient au tournage longitudinal en plus du rainurage. La géométrie DL est donc également disponible avec un rayon d'angle de 0,4 mm (0,016"). Le contrôle efficace des copeaux grâce aux géométries de rupture de copeaux garantit une qualité de surface élevée sur les flancs de la rainure et l'arête de coupe principale droite produit une base proprement finie. Conçues comme des plaquettes de rainurage neutres, elles peuvent être serrées dans des queues carrées avec refroidissement interne à gauche et à droite. Les dimensions des porte-outils sont de 20 x 20 mm (0,787 x 0,787« ) et 25 x 25 mm (0,984 x 0,984 »). Une vis de serrage fixe la plaquette de rainurage avec précision et en toute sécurité dans le logement central. Horn propose également des cassettes de serrage de type 220 pour le système de porte-outils modulaire.