To ensure that particularly gifted children continue to receive support beyond primary school, the Hector Children's Academy in Tübingen cooperates with a number of training centres in Tübingen, including the one run by Paul Horn GmbH.

HORN is gradually switching its packaging to recycled materials with immediate effect.

GM geometry: At EMO 2025, HORN is expanding its Supermini system with sintered geometries to include a variant for turning threads.

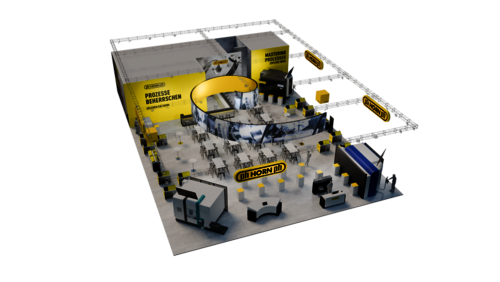

At EMO Hannover 2025, HORN will be presenting numerous exhibits, ,a wide variety of tool solutions and live machining on 580 square meters.

With the new PCD milling programme of the DM50 series, HORN offers a replaceable head milling system for the economical machining of aluminium.

From 14th to 16th May 2025, Paul Horn GmbH opened its doors for the ninth time to around 3,300 visitors from a total of 33 countries.

Reliable lead-free machining with HORN tools.

The new HORN chip-breaking geometry specifically for the Mini tool system types 108, 111 and 114.

Grooving, parting-off and threading: HORN's DC circular milling system is universally applicable to numerous milling operations.

The new PCD milling programme from HORN, with a focus on productive and reliable machining of aluminium, includes a wide range of standard and special tools from end mills to complex and modular combination tools.

"As part of our in-house HORN Academy, we are able to adapt the qualifications of our employees to the current requirements of the industry.", says Andrea Horn, responsible for the areas of further training, customer seminars and the Technology Days at the HORN Academy.