Mastering processes: mould milling at the limit

"Every block of stone contains a sculpture and it is the sculptor's job to discover it," the famous Renaissance artist Michelangelo once said. If the artist had traded in his hammer and chisel for today's modern five-axis machining centres and precision tools, we would be able to marvel at countless statues by the Italian sculptor today. Modern machining technology using multiple axes is what makes the productive milling of complex components possible. The advantages of five-axis positional and simultaneous milling are particularly evident in tool and mould making. In addition to precise machines and efficient programming, the tools play a major role in economic machining. With its tool portfolio and know-how, Paul Horn GmbH offers numerous milling solutions for tool and mould making.

As with a conventional milling machine, modern five-axis machining centres have three linear axes (X, Y, Z) each orthogonal to the other. In addition, the machine has two swivelling or rotary axes (A, B or C depending on the arrangement). These enable three-dimensional machining of the workpiece at different angles. Five-axis milling of a component does not necessarily mean that all axes move simultaneously. It means that five sides of a workpiece can be presented to the spindle for machining. If all axes move simultaneously to produce the required geometry of the workpiece to be produced, this is called five-axis simultaneous milling.

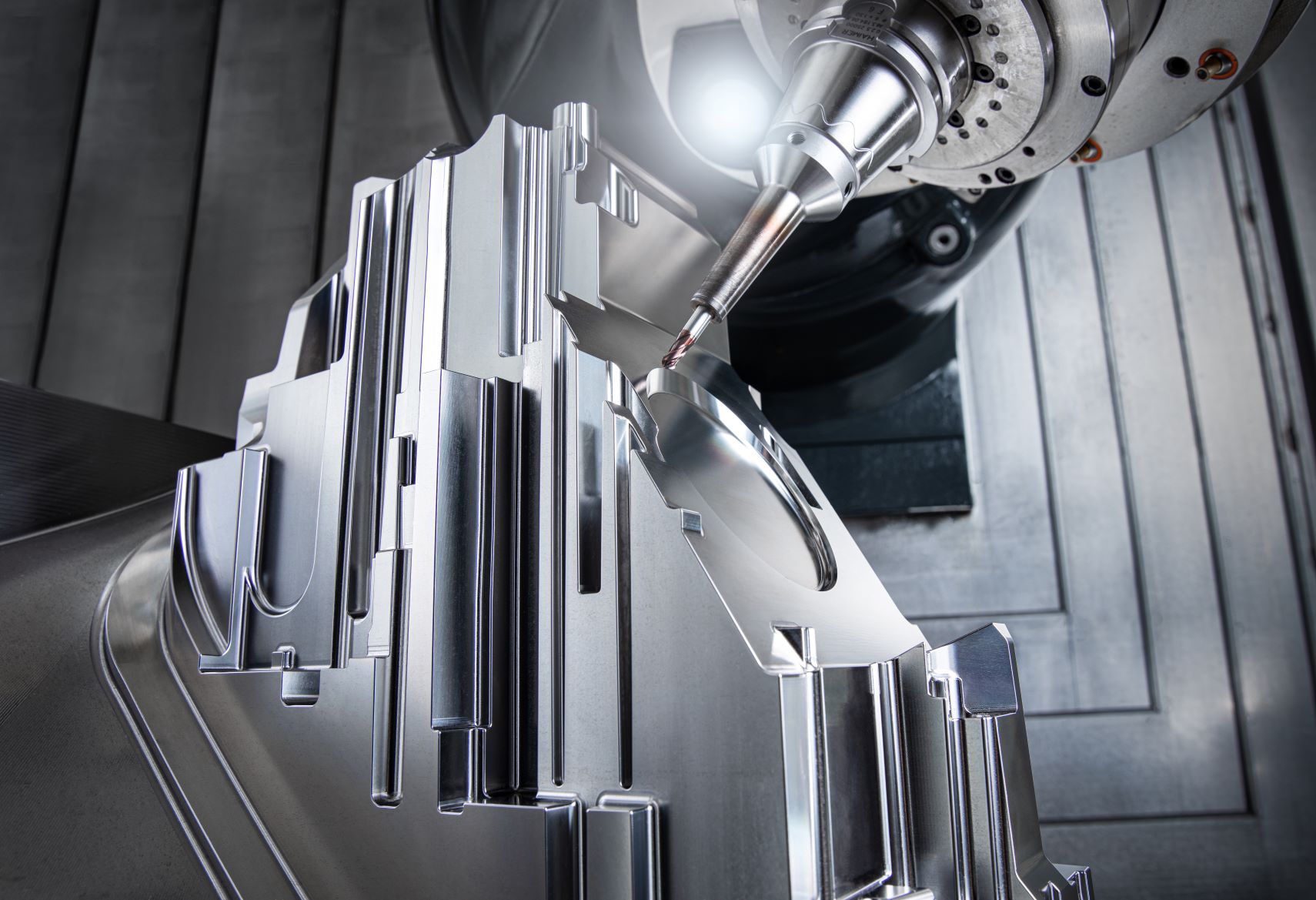

A large number of different Horn milling tools ensure high precision when machining a headlight mould. The component from the automotive industry is a significant challenge due to its various surfaces, shoulders and radii. Different high-feed milling cutters from the Horn DAH 8 system are used for roughing the mould. For finishing the mould, Horn engineers rely on different variants of the Horn DS tool system. In addition to various diameters of ball nose end mills, circular segment end mills are used. The advantage of the latter milling cutters, in contrast to ball or torus milling cutters, is that fewer passes are required when machining free-form surfaces, while the surface quality remains the same. This is particularly evident in the machining time for a given surface quality. Particular attention is paid to the transitions between the individual surfaces and the high surface quality that can be achieved.