Aluminium - high-performance milling solutions for a versatile material

Light, versatile, demanding - aluminium requires high-performance tools, stable processes and precise coordination of all parameters for series production. Whether in the automotive, medical, mechanical and plant engineering or electronics industry, aluminium alloys combine low weight with high strength, superior corrosion resistance and excellent recyclability. Despite its fundamentally good machinability, the material often presents users with challenges. Adhesion, built-up edges or bird‘s nesting can impair process reliability, particularly when milling. Precise coordination of tool geometry, grade, cutting data and coolant is therefore crucial for cost-effective machining. With its tool portfolio, Paul Horn GmbH offers numerous systems that enable economical machining.

The global importance of aluminium is reflected in the production figures. Over 60 million tonnes of the light metal are produced worldwide every year, with Asia and especially China playing a leading role. Aluminium is the third most common element in the earth's crust after oxygen and silicon, but it occurs exclusvely in a bound state. Aluminium is extracted industrially from bauxite using the Bayer process and subsequent molten salt electrolysis. The mechanical properties can be adapted using specific alloying elements such as silicon, magnesium, copper or zinc, which in turn directly affects machining behaviour.

Pronounced adhesion tendency

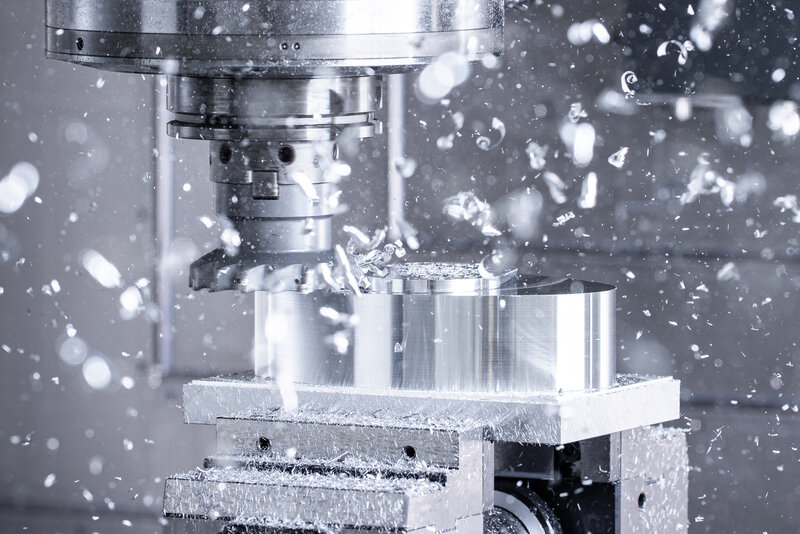

The material-specific properties are particularly evident when milling aluminium. Although the metal’s low hardness and low melting point favour high cutting speeds, they also lead to a pronounced tendency towards adhesion. Without appropriate measures, built-up edges can form, negatively impacting both the surface quality of the workpiece and tool life. Modern milling tools for aluminium are therefore characterised by sharp cutting edges, polished rake faces and special chip breaking geometries that support smooth chip evacuation. In addition, coatings with good anti-friction properties are used or, depending on the application, intentionally uncoated cutting edges are employed to maximise the tool’s sharpness.

HORN offers a comprehensive range of milling tools for aluminium machining, ranging from solid carbide milling cutters and circular milling tools to PCD and MCD solutions. Single-edged or double-edged tools with large chip clearance pockets play a key role, particularly when milling at high metal removal rates. They enable elevated feed rates and cutting speeds without impeding chip flow. Typical applications include pocket milling, plunging and trimming of aluminium components at high material removal rates.

Polycrystalline diamond

Diamond-tipped tools are primarily used for more demanding tasks and long tool life. Due to its high wear resistance and low adhesion tendency, polycrystalline diamond is ideal for milling of aluminium alloys, especially in high-volume production. The sharp cutting edges deliver high surface quality and stable processes, even when the cutting parameters are high. In addition to performing conventional turning operations, PCD has therefore become particularly well established in milling applications, for example in face milling of structural components or contour milling of complex geometries.

In recent years, Horn has consistently expanded its PCD portfolio and now offers not only PCD-tipped indexable inserts but also milling tools with a solid carbide, monobloc cutting head specifically designed for high-performance machining. These tools were first presented in a standardised range in 2024 and cover numerous applications, not only machining of aluminium but also other non-ferrous materials. The tool system enables high rigidity and excellent concentricity, which is directly reflected in surface quality and process stability.

New potential in high-performance machining

One example of this is the DG replaceable-head system with PCD cutting edges, which is based on an existing carbide system and has been expanded to include diamond-tipped cutting edges. Thanks to the modular design, different shank options in steel or carbide are available, making the system suitable for applications with large overhangs. Another highlight is a face milling system with precise concentricity and axial run-out characteristics. The rigidity of the system allows cutting values that push even high-performance milling machines to their limits and opens up new potential in high-performance machining.

For applications where a high-polish surface finish is required, such as in tool and mould making, cutting with monocrystalline diamonds is employed. This cutting material enables a milled surface quality that eliminates the need for subsequent polishing. It not only saves time, but also increases the reproducibility of component quality. The reliability of the process is a crucial advantage, especially for components whose surface will later be coated or chrome-plated.

Consistent quality over long service life

The increasing use of aluminium components, for example through new production technologies such as gigacasting in the automotive industry, underlines the importance of high-performance milling solutions. At the same time, the use of materials is changing, which places new demands on flexibility and precision. Modern milling tools must therefore not only enable high removal rates, but also ensure consistent quality over a long service lifetime. With coordinated tool concepts, innovative grades and application-specific geometries, these requirements can be met and the economical machining of aluminium sustainably optimised.